Take your productivity to the next level with Eagle Lasers

AUTOMATION FOR NON-STOP PRODUCTION

AUTOMATION+MACHINE

FROM ONE SUPPLIER

What our machine can cut or automation can handle.

Automated material handling and storage systems are crucial in today’s laser cutting industry, enabling manufacturers to fully exploit their machines capabilities.

These solutions streamline material Handling and logistics, optimise the production process, reduce downtime, waste and cost per part while boosting profitability

Eagle automation solutions guarantee the perfect fit with our laser cutting machines and have the most efficient parameters on the market.

Different TYPES OF EAGLE AUTOMATION

Automated material handling and storage systems have become essential in today’s laser cutting industry because they allow the manufacturer to fully exploit the machine’s capabilities. Through these solutions, you will optimize your production processes and minimize downtime, cost per part, and waste material, while increasing your productivity and, of course, your profits.

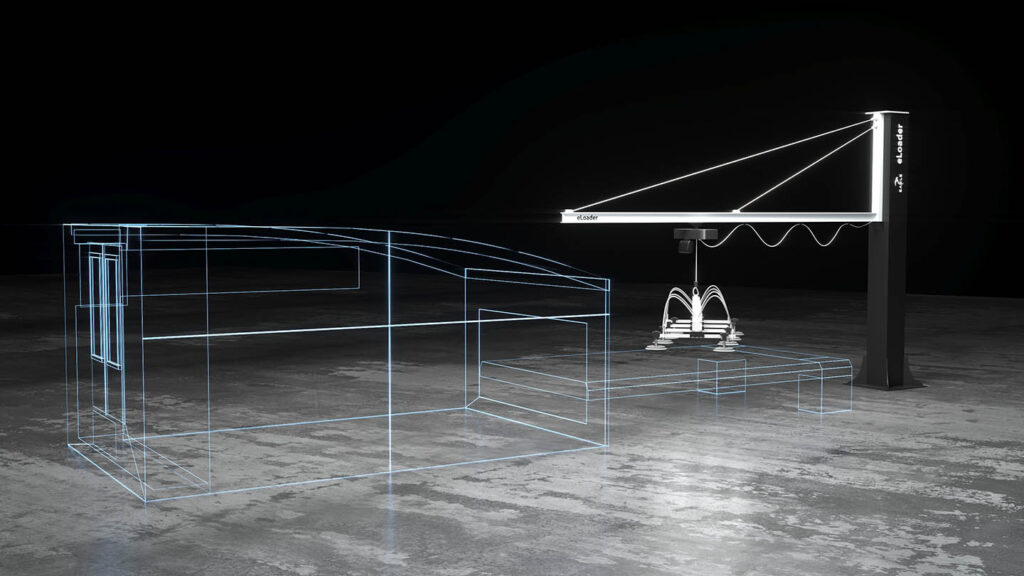

eLoader

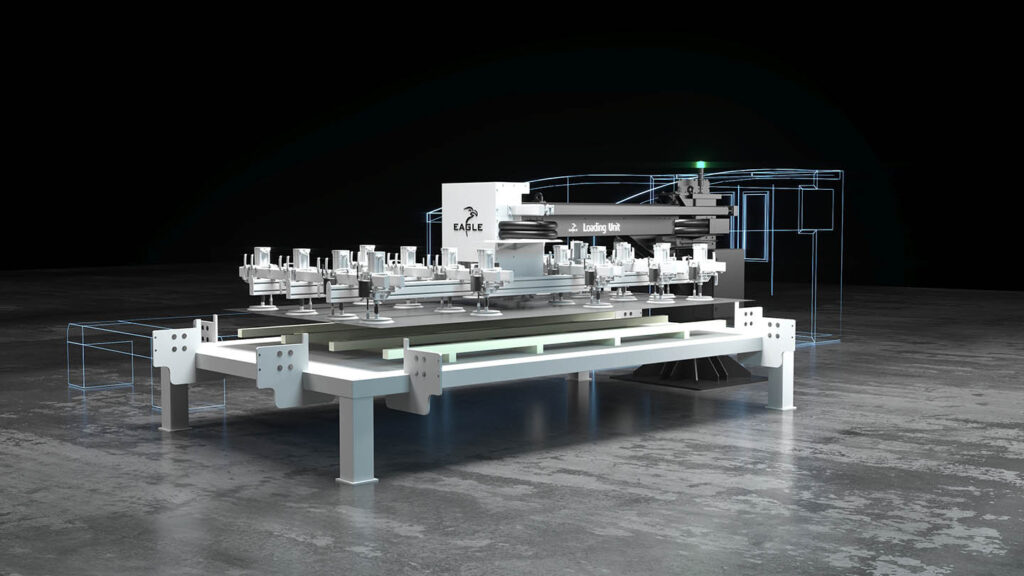

LoadingUnit

A simple solution that significantly optimises the material handling process while reducing operation time and production costs, the LoadingUnit is recommended for medium-capacity production companies that manufacture individual items or small batches.

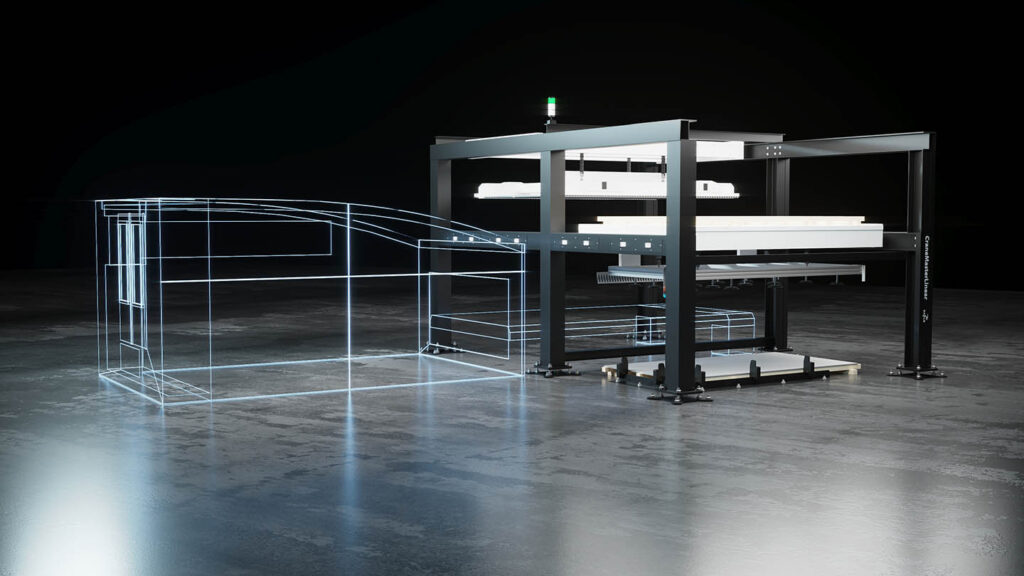

CraneMaster

CraneMasterLinear

CraneMasterStore

CraneMasterStoreLinear

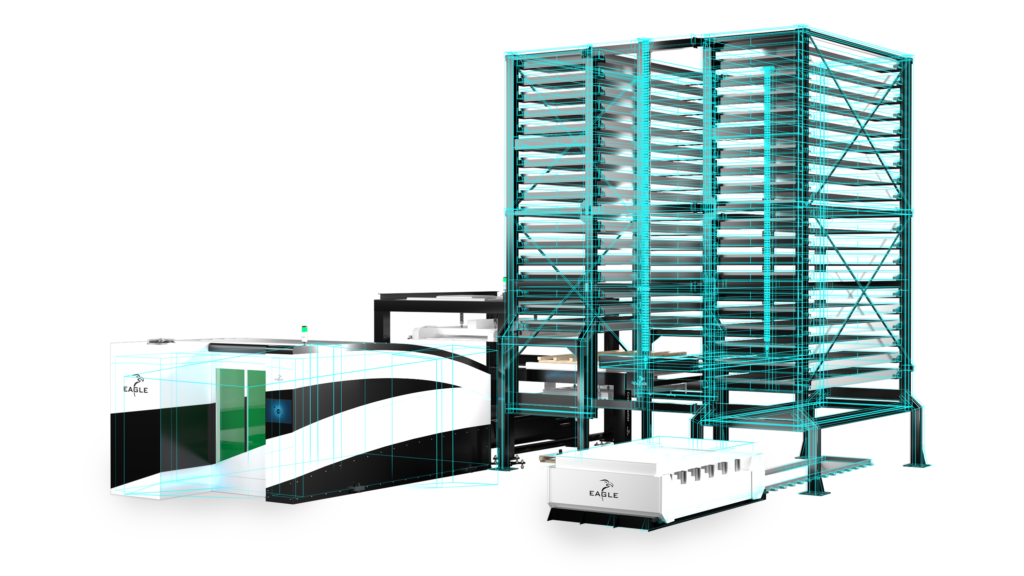

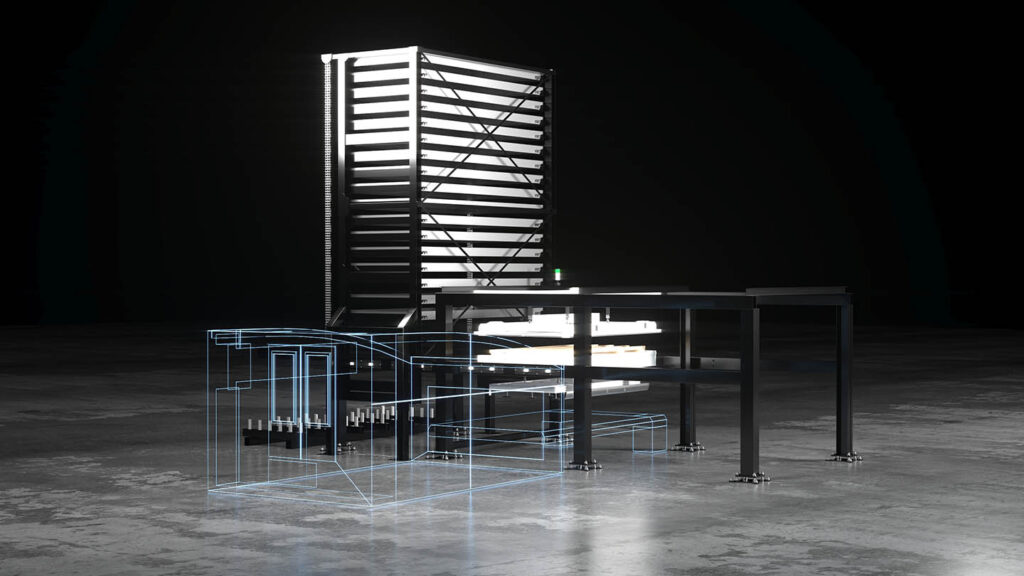

eTower1

The eTower1 Is a single tower storage system equipped with a loading/unloading station and universal shelves that can be used for raw material as well as for cut parts and remnants. It consists of a transport column equipped with a moving lift that transports the pallets between the storage shelves and the loading/unloading station.

The CraneMaster and eTower1 work seamlessly to optimise process logistics and material preparation and guarantee high storage density. Together, these automated systems make 24/7 unsupervised production possible helping you achieve the highest productivity.

eTower2

The eTower 2 is a two-tower warehouse system equipped with a loading/unloading station and universal shelves that can be used for raw material as well as for cut parts and remnants It consists of two transport columns equipped with moving lifts that transport the pallets between the storage shelves and the loading/unloading station.

The CraneMaster and eTower2 work seamlessly to optimise process logistics and material preparation and guarantee high storage density. Together, these automated systems make 24/7 unsupervised production possible helping you achieve the highest productivity.