The perfect combination of technology

Software that is powerful yet easy to use:

Our software suite covers all of the needs of a programmer, operator or supervisor. The programmer will be able to select the software modules that suit your production environment and integrate them into your enterprise system as required. The operator will have full control of the EAGLE Laser, be it carrying out large production runs or cutting an individual part from a remnant sheet. The supervisor will have a continuous flow of laser performance and productivity data at his or her fingertips. EAGLE’s software suite will provide efficiency, control, and profits.

Software available for EAGLE laser cutting machines:

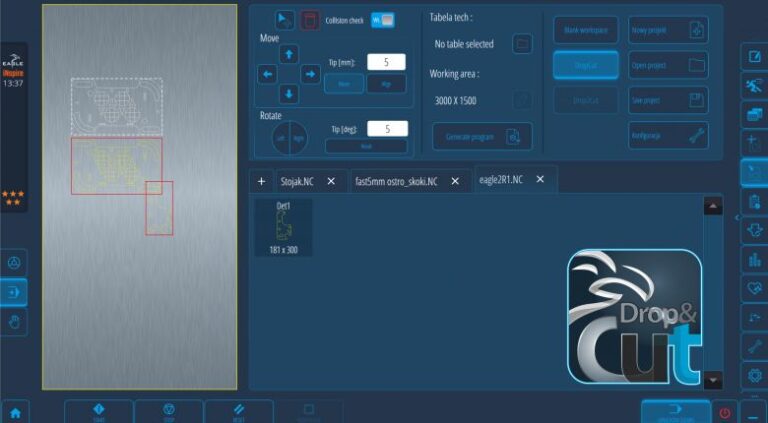

Drop 2 Cut - Fast Cutting

The Drop2Cut option provides identical functionality to Drop&Cut, but on a pallet that is outside the cabinet. A second video camera visualizes the external pallet. The laser can simultaneously cut a certain program inside the machine while the operator uses Drop2Cut to place and program a part on a pallet outside the machine. This system minimizes downtime.

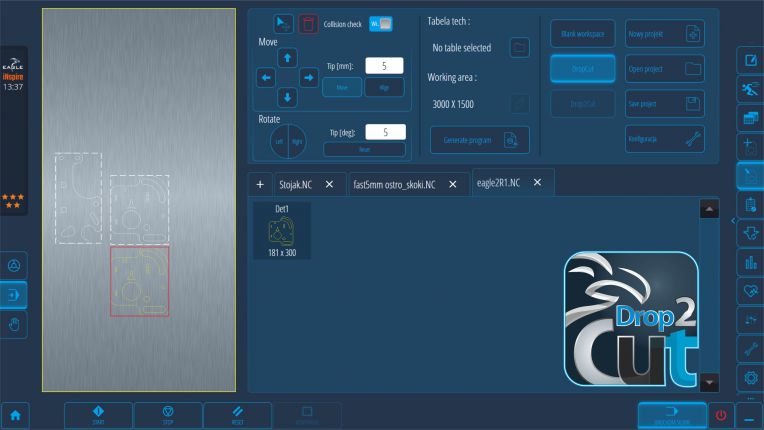

Drop & Cut - Fast Cutting

The patented Drop & Cut module of our software package allows efficient use to be made of residual material, even if the residue is irregularly shaped and full of holes and gaps. When you are in a hurry, Drop&Cut allows you to quickly manufacture one item directly on the machine without creating a new NC file.

A video camera inside the working area allows the Drop&Cut system to provide an image of the actual residue on the EAGLE computer screen. The operator can use our touch screen to drag a virtual outline of the part to be cut onto the image of the residue and quickly see whether it fits. The operator can also rotate the part if necessary in order to adapt it to the residue. The software will not allow the operator to cut out a part which does not fit inside the material. All of this can be accomplished without reprogramming the machine. This allows you to quickly deal with small jobs or the last few items of a production run.

CatLine - Cutting Thick Sheets

With very thick materials, CatLine reduces burr formation and improves the piercing and cutting of small contours and contours close to other contours.

Thanks to modifications to the laser source, the optical fiber and the eVa cutting head, we achieve unprecedented cutting quality with thick stainless steel and aluminum sheets, and exceptionally quick cutting of all thick sheets. The optics and the other parameters are adjusted in accordance with our process models while the part is being cut.

CatLine makes a 20% thickness increase possible with the same laser power, and improves thick sheet throughput time by up to 50%. High quality edges are manufactured, burr formation on aluminum and stainless steel is reduced by 80%, and the cutting process is stabilized for consistent results.

eRs Cloud - Everything Under Control

A modern reporting system that provides unlimited ways of analyzing and improving laser work cell performance. The system is based on the latest programming solutions. Reports which are generated in accordance with personalized settings can be flexibly created on the web site immediately after logging in. The reports cover all aspects of machine operation such as operator efficiency, setup times, idle times, spare part wear spare parts and the dynamics of gas and material usage. The attractive graphical design of the static and dynamic reports provides you with clear information about the laser cutting machine. If the system is linked to your ERP, the level of detail of the reports allows you to improve system efficiency and cost control.

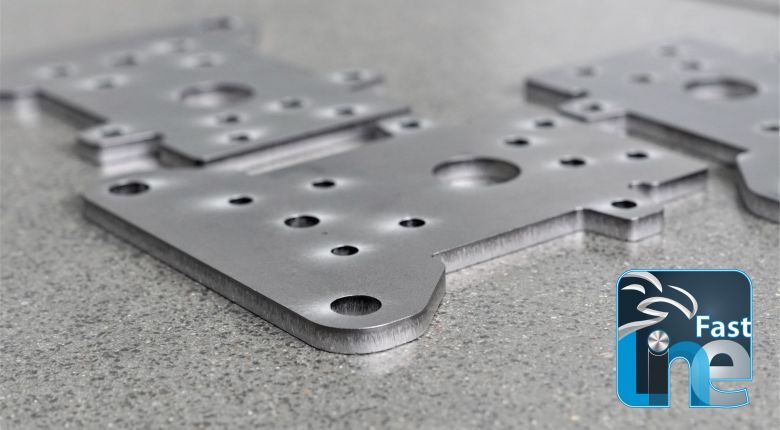

FastLine - Fast Cuting of Thin and Medium-Sized Sheets

Super – fast cutting of thin and medium thickness sheets up to approximately 6mm (.240”) thick (depending on the material and the laser power). Fastline has 2 primary functions:

• FlyCut – Fly cutting involves the piercing of relatively thin material at cutting speed, as opposed to stopping, piercing, and then moving. The head moves between contours arranged in an array at a constant speed without stopping to pierce. Cutting takes place by switching on the laser beam above the cutting lines and switching it off again between contours. If your part has an appropriate repetitive pattern, Flycut can significantly reduce the throughput time of the part, and can be used up to a thickness of 6 mm.

• FastCut – Fastcut involves “piercing on the fly” and significantly reduces the piercing time. Rather than stationary piercing, the system moves at an appropriate speed to reduce the piercing time, and then resumes at full speed as soon as possible. This option is used to cut sheets with a thickness of up to 12mm. This option improves the cutting efficiency of thin and medium thickness sheets by up to 30%.

eRis - New Philosophy of User Experience

The Eagle eRis graphical user interface is a new product from the eSoft software family. In conjunction with the Eagle laser cutter, it represents a completely new quality of interaction between human beings and external systems. Revolutionary design, new functionalities and the use of leading technologies in the field of software production are the characteristics of the new product. The application has been designed to fully exploit the potential of the touch screen that is installed in the machine. The modern user interface combines attractive design with the easy and ergonomic operation that we are familiar with from devices such as Smartphones, tablets and computers with touch screens. eRis makes integration with external Industry 4.0 systems possible. This gives the user the opportunity to plan production from A to Z, i.e. from order acceptance to the release of goods, including warehouse automation, warehouse towers and integration in an ERP system. The data obtained by eRis is used by the new eRs Cloud reporting system, which collects and processes it in the cloud.

CutEye - Ultra-Fast Sheet Detection

If you also need to reduce the time needed to locate the sheet on the shuttle table before cutting, CutEye’s rapid edge detection will meet this challenge. The CutEye rapid edge finder locates the sheet approximately 3 to 4 times faster, adjusts the cutting program to match the sheet location, and starts cutting. A sheet locating time of 5 seconds is normal for small to medium-sized sheets, with slightly longer for bigger sheets. The cutting head remains retracted during the edge finding cycle, allowing the machine to move at ultra-fast speed and avoiding the risk of collision.

eSoft - Laser Cutting Optimisation

EAGLE was involved in the development of this software family. eSoft is CAD/CAM software which has been specially designed for laser cutting machines. It is a tool that allows you to work on EAGLE laser cutting machines and, can also be used to program machines such as plasma and water jet cutting machines. The software has a high degree of efficiency and functionality.

eSoft is full-featured software that can keep a small to medium-sized company operating at peak efficiency. This package contains the full cutting technology that is needed to operate a laser, plasma, water jet or oxy-acetylene torch. This powerful software can import DXF, DWG, GEO, CDL, HPG, PLT, AAM, IGS, NC1 and CMC. It also includes a cutting simulation feature which helps you to cut your parts correctly, right from the very first part.